Integrated Business Planning (IBP) has delivered significant benefits to practicing businesses. According to a recent study conducted by Aberdeen Research, companies with a well-structured IBP process achieved the following benefits over a two-year period post IBP implementation:

- 17% improvement in profitability

- 10% increase in gross margin

- 7.5% increase in return on net assets (RONA)

Many companies are still running S&OP processes in Excel spreadsheets in fragmented siloes. This is simply no longer effective. The low hanging fruit has been picked, and in order to improve processes and stay competitive, companies must innovate their planning processes.

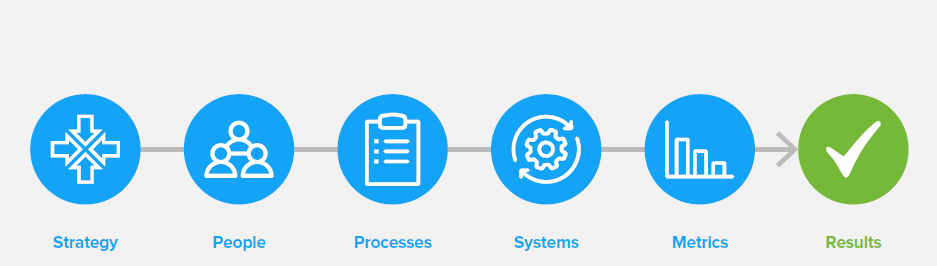

5 elements of an Integrated Business Planning Framework

1. Strategy

The first critical step is to align corporate and business unit strategy to the overall supply chain strategy, and then migrate to an aligned operating model. This model provides the framework for the IBP process. With a comprehensive understanding of corporate strategy, an optimal supply chain structure and operations can be designed.

A strategically-aligned IBP process can deliver game- changing benefits to the business. Rather than focusing solely on sales revenue, or simply balancing supply and demand projections, IBP can help practitioners make decisions that generate the highest profit for the entire company.

2. People

The IBP project lead is ideally assigned from the senior management team. This means either the CEO or one of his/her direct reports would fulfill this role since the process will align myriad functions with the overall business strategy and unite the different functions into one homogenous process.

As with any project, there must be a plan, and it must be communicated effectively so everyone is aligned and aware of their role and the team's expectations.

To be successful, the plan must also have well-defined and achievable milestones for the project team. Discipline is a critical factor in the success of an IBP project and creating a solid foundation will ensure a successful implementation process.

3. Processes

The key to implementing a fully integrated and optimized planning process is to follow a structured approach in line with the integrated business planning framework.

A successful IBP implementation process relies on the following steps:

- Define where you are now

- Define where you need to be

- Leverage keys to success

- Kaizen (constant improvement)

4. Systems

IBP is not simple—it requires both the right people, and the right supporting software infrastructure. Excel spreadsheets, and even most business intelligence (BI) solutions, are not designed for this purpose and do not have the power to support the complexity required in a straightforward and scalable way.

The right technology becomes the enabler for the entire IBP process. The right solution should be built on supply chain modeling and optimization. It will enable overall profit-driven decision making through “what-if” scenarios. At a tactical level, it will give the best inventory management answers considering a complex range of factors such as expiry dates, lead times, storage capacities, and resource and asset utilization. It will take a holistic view of the entire supply chain network and deliver the best plan that considers all business factors.

5. Metrics

Effective IBP systems are dependent upon accurate and actionable data. Data integrity is essential and accurate data is a key enabler in the process needed to apply precepts of science to data management.

Establishing data governance model over the IBP process ensures consistency and data integrity, and a focus on continuous process improvement.

In addition, key performance indicators (KPIs) are vital to accurately measure the effectiveness of strategic execution, including:

- Forecast accuracy

- Fill rate

- Obsolete stock

- Inventory turnover rate

- Overtime

- Procure cost to sales

- Utilisation rate

English

English  Vietnamese

Vietnamese