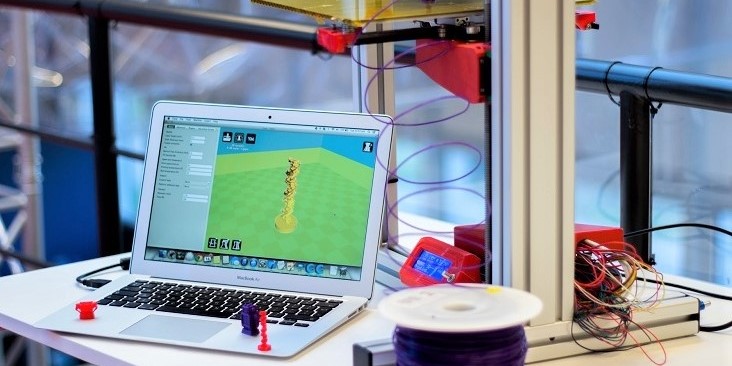

Additive manufacturing (AM) is a method of manufacturing products by adding layer upon layer of materials, navigated by a computer-aided-design (CAD) software. Sounds familiar? It is because this is also the concept of 3D printing.

In some cases, Additive Manufacturing and 3D printing are used interchangeably despite some slight differences between the two terms. This may be the first time you’ve ever heard of either of them, but contrary to normal belief, AM/ 3D printing has been around for decades.

Read more: Manufacturers adapt to Industry 4.0

What is Additive Manufacturing?

To simply put, AM is a process that creates a physical object from a digital design. There are many subsets of technologies that fall under the AM group, including the well-known 3D printing.

There are mixed views of the similarities between 3D printing and AM. Some say that these two are the same, others just disagree completely. According to Fisher Unitech, one uses 3D printing when there's a request for inexpensive, quick, easy to use items. If tougher, accurate, and rigid components are required, then it is best to use AM.

Other subsets of AM are Rapid Prototyping, Direct Digital Manufacturing, layered manufacturing and additive fabrication.

Additive Manufacturing is revolutionising the way business manufacturing products. We are able to tweak the design of the product with just a few mouse clicks or fabricate complicated shaped objects without the needs for moulds.

Read more: Can manufacturers meet changing demand without sacrificing efficiency?

How does it work?

The traditional way of fabricating products involves carving, combining or shaping the end results out of blocks of materials. With AM, the three-dimensional object is built one wafer-thin layer at a time. Each layer is fused on top of the preceding one by fully, or partially, melting the material that made up the product.

The materials used in AM can be metal powder, thermoplastics, ceramics, composites, glass, or in some instances, chocolate.

The process requires the objects being digitally designed and "sliced up" using CAD software. The software also plays a role in guiding the nozzle (or print head) to deposit the material.

Alternatively, laser or electron beam can also be used instead of the nozzle to melts the powdered material. Once done, the object is left to cool/ cure so all the layers can bond with each other.

Benefits of Additive Manufacturing

Additive Manufacturing essentially takes production to a whole new level. The traditional method already offers a wide range of shapes, designs, geometries possible, AM provides even more flexibility.

For example, Additive Manufacturing can create shapes that have a hollow centre as one strong piece. With the traditional method, this case may require welding and attaching different parts to create the component.

The products created using the AM processes are also stronger, lighter, more cost-effective, and the time from design to execution is shortened. Long were the days when your engineers have to conduct rows and rows of meeting just to finish the design. With CAD software, changes can be done with a few mouse clicks and the production can take place literally overnight.

Read more: Manufacturers are embracing innovation and here's why

Additive Manufacturing applications

In the past, the designs are limited to only what the production chain had to offer. Now, the designs can certainly influence the production chain. AM applications in manufacturing are practically endless.

In automotive

The AM processes eliminate the need for a machinist to interpret the drawings as everything now can be done in three-dimensional, with computer-aided software, which then feeds the data directly to the machine. All specifications are replicated exactly the same as the design but the lead time is slashed to 40-90% compares to the conventional manufacturing method.

Ford Motor Company is one of the big brands that leveraged the in-house AM process to create prototypes. The process was estimated to save the company approximately four months and millions of dollars in production.

In aerospace

Due to its ability to produce complex geometry yet lightweight and durable parts, it makes sense for AM to be quickly adopted into aerospace.

In the 2017 Paris Air Show, Boeing 787 Dreamliner - the first FAA-approved, 3D printed structural titanium components commercial aeroplane, were displayed and has been receiving many positive feedbacks.

In medicine

Additive Manufacturing in medicine? You mean the making of artificial limbs and dental restorations? AM can go even beyond that and produce human skin, and maybe one day, other complicated human organs too.

It's still too early to conclude anything but various medical laboratories have been successful in creating bone, cartilage, and blood vessels with the help of AM.

Just like in the industrial area, Additive Manufacturing is revolutionising the field of medicine. There is a possible future where the healthcare sector is able to create body parts on demand in addition to tremendously shorten transplants waiting lists. For the moment, AM is being used to produce customised equipment, surgical tools as well as moulds for dental implants.

English

English  Vietnamese

Vietnamese