The end-to-end business process is the ultimate goal that ERP offers to enterprises. It helps users manage and access any operation more easily.

Overview

Currently, many manufacturing companies are facing difficulties which deny them visibility into their entire supply chain information prior to making any decisions such as:

- What materials and where they put in used in the production process.

- Production statistics is updated inaccurately.

- The Sales Order cannot be fulfilled on time.

So what is the best approach to managing all operations more efficiently? Being the primary platform for collaborating all limited resources of a business, ERP has been innovated in order to manage the manufacturing sector more efficiently. Companies can control the production process in a way that can save more time and cost; the management information is more accurate with real-time insights to help push business performance.

Therefore, within this context, we will discover what benefits ERP will bring to improve the performance of manufacturing process.

The End–to–End process

The end-to-end process is a guiding workflow in which you can easily access any operation you are in charge of, from creating Promise to Customer to monitoring Demand/ Supply Summary, then calculating Net Requirement Planning of Materials, from to collaborating day-to-day operations on the shop floor to prioritising resources to meet demand, from production statistics/ reporting to Delivery In Full On Time.

The process is designed for not only streamlining efforts and collaboration but also pegging all related information from sales down to production in such a way that all costing data can be pulled from the system.

Planning Summary (to meet promise date)

Balance Demand and Supply in a period of time

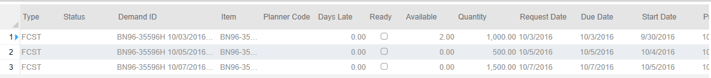

Through an ERP system, when an order has been created, a planning summary report will be generated automatically so that managers can use reliable information such as Forecast, Demand quantity and Order Date to push productivity in order to fulfill the customer orders on-time and produce more finished goods for further orders.

When you drill down into details for each demand, the ERP system will generate a Demand Summary so that you can view specific demand ID whether they are a Job Order or Customer Order, MPS or Forecast.

Material Planning

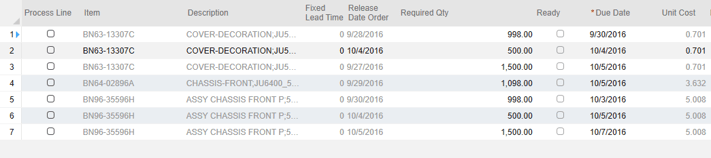

- In order to keep the production flow running without interruption, an ERP system will automatically display a list of raw materials required for production so that you can manage the material quantity more efficiently by planning and calculating net requirements for manufactured items.

- In case BOMs are not enough to supply the manufacturing process, the system will measure the net requirements in purchase requisitions and convert into Purchase Order. Therefore, the materials will be delivered as soon as possible to prepare for upcoming transactions.

- Finally, the system will convert the entire production planning into jobs orders or purchase requirements for further collaboration.

Resource Gantt Chart - Scheduler

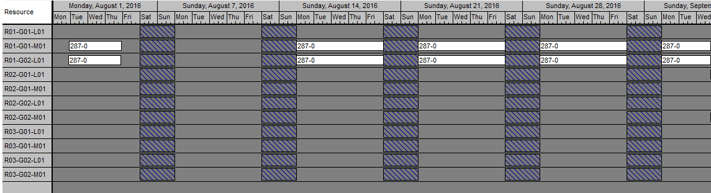

- After allocating materials to operations, the ERP system will generate a Resource Gantt Chart – Scheduler for you to visualise all firmed/ released job orders in timing range. In other words, it allows you to view a graphical representation of the schedule for a particular resource or group of production in the system with specific information regarding its operations.

- Moreover, the manager can manage the job transactions more efficiently by separating job orders group into various production areas in order to prevent overwriting production schedule.

- In addition, based on information shown in Resource Gantt Chart such as Start and End date of job transaction, information of finished goods with its current status, you can decide which job order is more prioritised than others and change the other operation schedule.

Materials Reporting

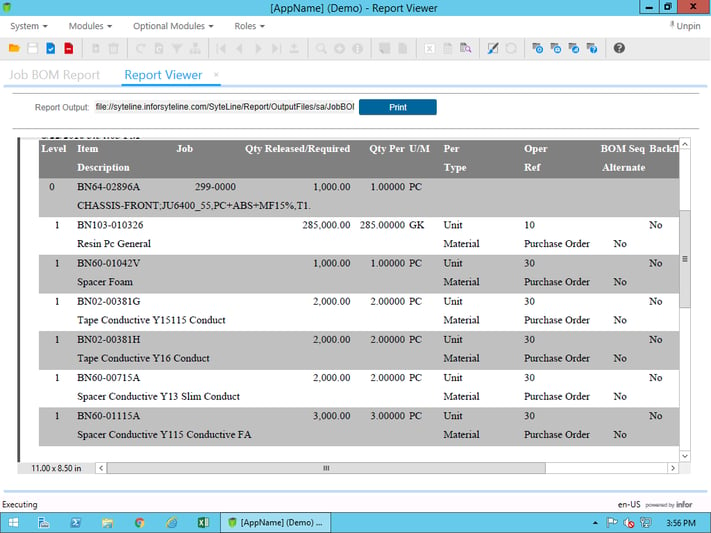

If you want to review the job material used for production, ERP will also provide a Current Material report which includes:

- Materials stay– in–line with its respective operations

- The current number of quantity used for production which defined in finished good’s BOM.

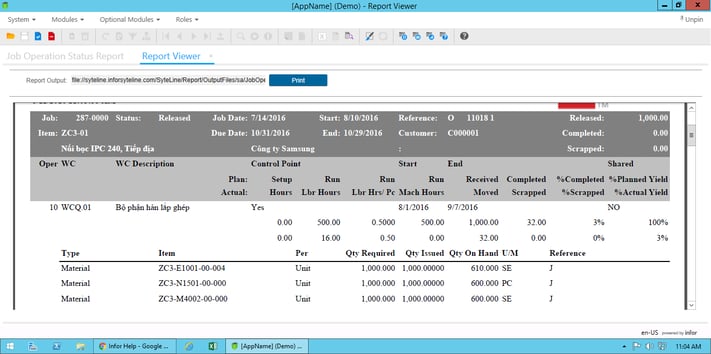

Job Order Reporting

An ERP system will also be able to update current job operation status such as:

- Labour that working on its operations

- Machine that is used for manufacturing

- Time duration for production

- Total quantity completed and scrapped recently

Therefore, the CEOs can track the current production activities anytime, anywhere.

The production efficiency of the order

- For whom you will produce

- What type of items you will produce

- How many items you will produce

- How much it costs (materials, labour, overhead)

- Production analysis for both efficiency and price

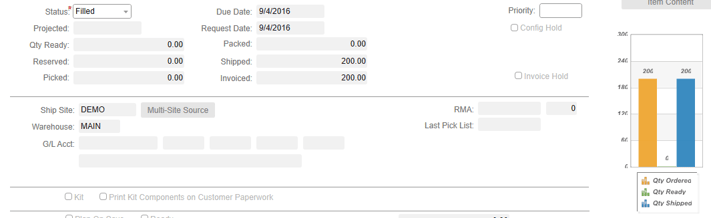

Order Shipping

When the job order is finished, the company can make a delivery order easily on their ERP system so that the order can be delivered on-time or even earlier than scheduling.

After posting the shipping requirement, this form will be delivered to the Shipping Centre which then begins delivering the orders to the final destination.

After shipping the orders, information of the customer order will be updated into customer order form so that managers can follow up the current activities of the company anytime and anywhere.

Benefits

There are some values that you will gain when running the whole end-to-end process:

- ERP helps the user to visualise the big picture of production module by running the End–to–End process.

- The result of completing job order will be more practical

- Business can manage job orders more efficiently in terms of labour, materials and the capacity of its machines.

- The manager can prevent from past due purchase order or delivery for each customer order.

As a consequence, the relationship between the company and customers will be enhanced as well.

English

English  Vietnamese

Vietnamese