Today’s furniture and fixtures manufacturers are facing volatile raw materials pricing, fluctuating consumer demand, and increased global competition. Manufacturers are competing in one of the most notable movements in the Furniture and Fixtures industry: customers expect higher quality and greater value than ever before, as well as more customisation options, including being able to configure selections and purchase online.

Trends and opportunities for the Furniture and Fixtures industry

With new trends to keep up with, such as more automation, more environmental processes, it is critical for businesses to be aware and prepared for these changes. Along with new trends are many new opportunities for furniture businesses to grasp and thrive.

Read more: Moving from on-premises to Cloud ERP

Industry Trends

Modern Designs

Today’s customers prefer designs that are customised, efficient and innovative. Manufacturers have to constantly update their products and come up with new ideas that meet today customers’ demand and standards.

Emerging Countries as Manufacturing Hubs

Furnishing businesses are moving to the emerging countries as manufacturing hubs for the lower labour and manufacturing costs.

Automation processes

Automation processes, including computer integrated manufacturing and flexible manufacturing systems, help boost the manufacturers’ productivity significantly.

Sustainable Products

With the rising awareness for the environmental problem of consumers, manufacturers must adapt to the eco-friendly products. Recycling materials like wood, glass, plastic, and metal are worth experimenting and can help businesses to win over the consumers’ favour.

Read more: Finding the Right ERP Solution for ManufacturingIndustry Opportunities

Furniture Leasing

The new trend – leasing furniture, allows the end users to upgrade to newer furnishings more gradually. This results in a higher profit compared to the traditional single-spend, competitive bid purchases.

Emerging Markets

Besides joining the emerging markets for a lower manufacturing cost, manufacturers are planning to exploit the potential of these markets. Any manufacturer that wants to expand and invest overseas should consider establishing a business in the emerging countries for their thriving economies.

Automation Improvements

Smart factories, with automated processes, is an essential movement for modern manufacturers. Integrating computer-controlled automation processes can result in boosted mass production efficiency.

Leveraging Internet Capabilities

Undoubtedly, expanding the business to the internet is a must for businesses, as customers today have the tendency to do the shopping online. There is an increasing number of manufacturers have already offered their products directly to consumers through their websites.

Read more: Challenges in Selecting ERP Solutions for Manufacturing

Challenges in the Furniture and Fixtures industry

Business Challenges

High Transportation Costs

Furniture takes up a lot of space for transporting, therefore, logistics is significantly costlier for today’s manufacturers. They need to manage supply chains more efficiently so as to reduce the total costs of suppliers, distribution, and retail.

Product Complexity

Resulting from the trend of automating processes, and the demand for more sophisticated function and design products, manufacturers need a system that provides better engineering and tighter manufacturing specifications to produce the complex components.

Volatile Raw Material Prices

The furniture industry has to deal with significant raw materials price fluctuation. For instance, a sudden rise in the raw materials costs can negatively affect the profit margins, if higher costs cannot be passed on to customers.

Low-Cost Import Competition

Manufacturers are competing to build new plants and expanding to emerging markets to lower the labour expense and importing cost.

Read more: [Infographic] 4 Signs that It’s Time to Upgrade Your ERP System

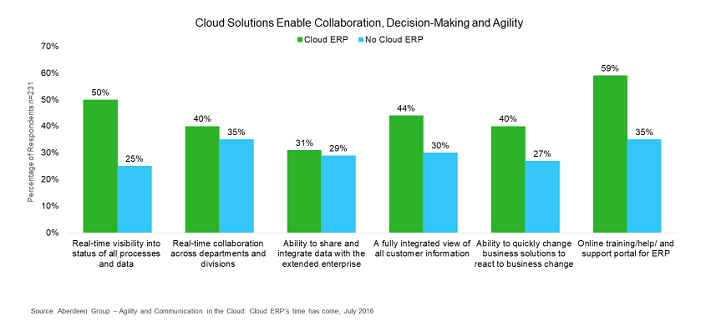

Improve the Production Cycles with an ERP solution

A research by the Aberdeen Group has stated that 51% of the respondents said that they need to speed up the product launch before their competitor; and another approximately 48% of the manufacturers want to meet the market demand for higher performance, more complex and customised products. Hence the need for a system/a solution to enhance the production cycles, reduce costs and to make better decisions.

Priorities for executives in the Furniture and Fixtures industry

.png?width=710&name=Furniture%202%20(2).png)

Subscribe to TRG Blog and get instant notifications when we publish new content or talk to our expert by requesting a free Infor CloudSuite Industrial demo today!

English

English  Vietnamese

Vietnamese